EC-04 EVO, THE LAST DANCE

EC-04 EVO, The last dance

After the performance with EC-04, it’s time for reliability with EC-04 EVO. Thanks to the lessons learned during competitions and feedback from judges, the ESTACA Formula Team’s latest combustion engine single-seater aims to achieve the team’s best results.

The EC-04 EVO project began in September 2024, in parallel with the start of the design of some elements of EC-05.

With many of the students who were involved in the manufacture of EC-04 still on board and new members motivated to achieve historic results for the association, the desire to develop the EFT’s latest combustion engine single-seater is remarkable.

We therefore designed the EC-04 EVO with a clear objective: to maximize reliability while maintaining a high level of performance. To meet the requirements of Formula Student, we took up the challenge of developing this single-seater in just one year, like the best teams in the world, adopting professional methods at every stage of its development and manufacture.

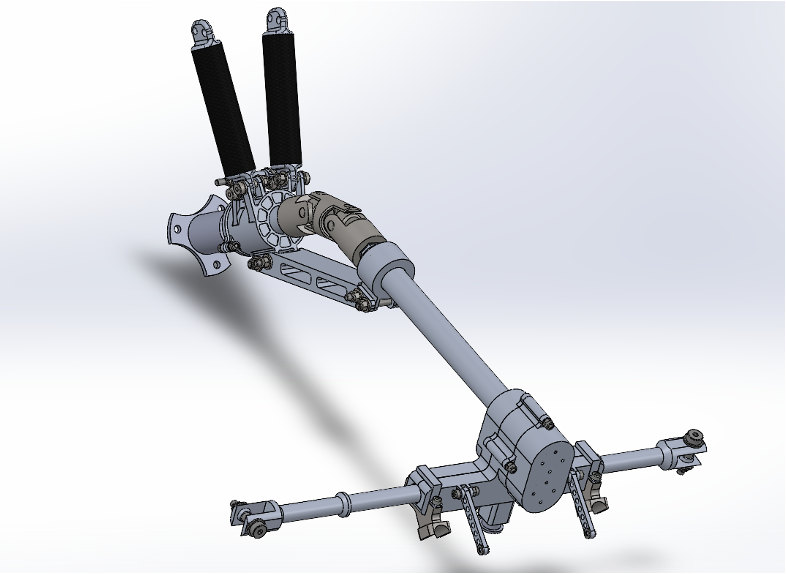

Suspensions & steerings:

Mechanical Design and Reliability

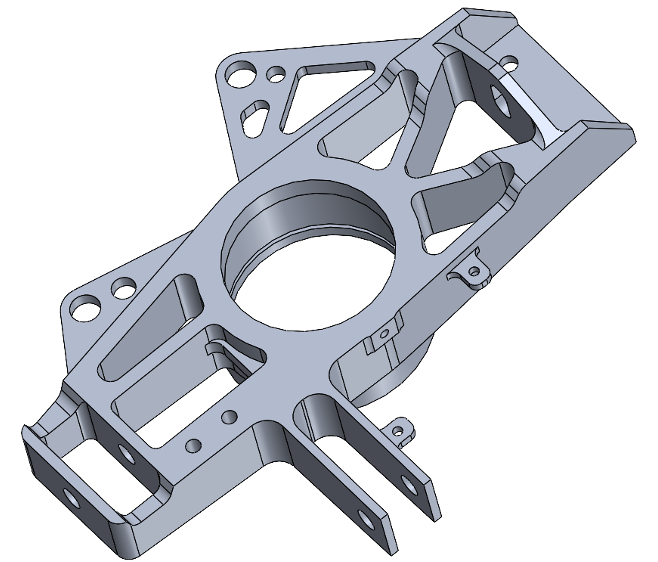

To guarantee flawless endurance during dynamic testing, we redesigned the mechanical layout with robustness in mind. The hub carrier has been optimized for integration, ensuring precise bearing guidance to eliminate functional play and withstand intense lateral forces. At the same time, the steering system has been redesigned to offer a more direct response, allowing the driver to position the car with millimeter precision.

Structural Optimization

The quest for performance inevitably involves reducing unsprung weight without sacrificing rigidity. We applied topological optimization methods to the rockers to maximize the transfer of forces to the shock absorbers while minimizing the amount of material used. Similarly, the anti-roll bar was subjected to rigorous finite element analysis, illustrated by our stress maps, in order to adjust its stiffness and perfectly control cornering behavior.

Chassis : the improvement

The EC-04 chassis proved itself in competition, so we decided to use the same base for the EC-04 EVO.

For this new single-seater, we focused on rigorous structural optimization and redesigned driver ergonomics. The goal: to maximize rigidity while ensuring seamless integration of mechanical and electronic systems.

Structure and Rigidity:

The major development in the EVO version lies in the optimization of our tubular steel structure. Thanks to a detailed analysis of stresses and a strategic modification of the geometry of the frame (particularly on the side tubes and flat bottom), we have significantly improved the car’s dynamic behavior.

This increase in rigidity allows the suspension to work more efficiently and provides the driver with more precise feedback on the track.

EC-04

EC-04 EVO

The drivetrain : focus on the cooling

The reliability of our motorization is based on a rigorous design methodology, where nothing is left to chance. We followed a strict development cycle, beginning with a documentation and advanced digital modeling phase to accurately predict radiator temperature changes and dissipation requirements.

To validate these theoretical models, we designed and manufactured a specific aerodynamic test bench. This instrumented device, comprising a blower, a honeycomb grille to laminate the air flow, and thermocouples, enabled us to compare our simulations with reality. The correlation obtained between the calculated curves and the physical measurements validates our cooling architecture even before its implementation on the car.

For EC-04 EVO, our approach to the wiring harness was pragmatic: capitalize on what already exists to maximize reliability. We took the proven EC-04 wiring harness as a basis and made critical optimizations to secure each connection. This groundwork enabled us to integrate new vital components, including an alternator for energy autonomy and a controlled cooling system for the motor.

We have integrated the DL1 PRO module coupled with the DASH4PRO pilot interface, offering real-time performance visualization. Thanks to a comprehensive network of chassis and engine sensors, we are now able to transform each lap into actionable data.

The aerodynamics : new wings

The aerodynamics of the EC-04 EVO did not start from scratch, but rather from a critical and constructive analysis. We based our development on comprehensive feedback from the previous single-seater, the EC-04, while incorporating lessons learned from technical exchanges with other Formula Student teams.

Once again this year, by optimizing the design and manufacturing methods, we have managed to produce an aerodynamic package weighing just 7.5 kg.

The results of this redesign are clear. Numerical simulations (CFD) confirm a lift coefficient (SCz) of -3.19, marking a 36% increase in downforce while maintaining an aerodynamic finesse of 2, up 30%. These theoretical figures did not remain virtual: they were tested in reality during wind tunnel sessions. The use of smoke and flow visualization paint on the actual car allowed us to validate the correlation between our numerical models and the physical flow of air around the bodywork.

Final step : the competitions

To perform this “Last Dance” of the ESTACA Formula Team’s thermal era, EC-04 EVO will compete in two competitions in 2024: Formula Student Spain and Alpe Adria.

The goal is simple: push EC-04 EVO to its limits in all dynamic events and achieve the best results in static events.